This Studer is, however, different from the rest, because it originally belonged to BBC Bristol. It therefore bears the hallmarks of a machine specifically adapted for broadcast use.

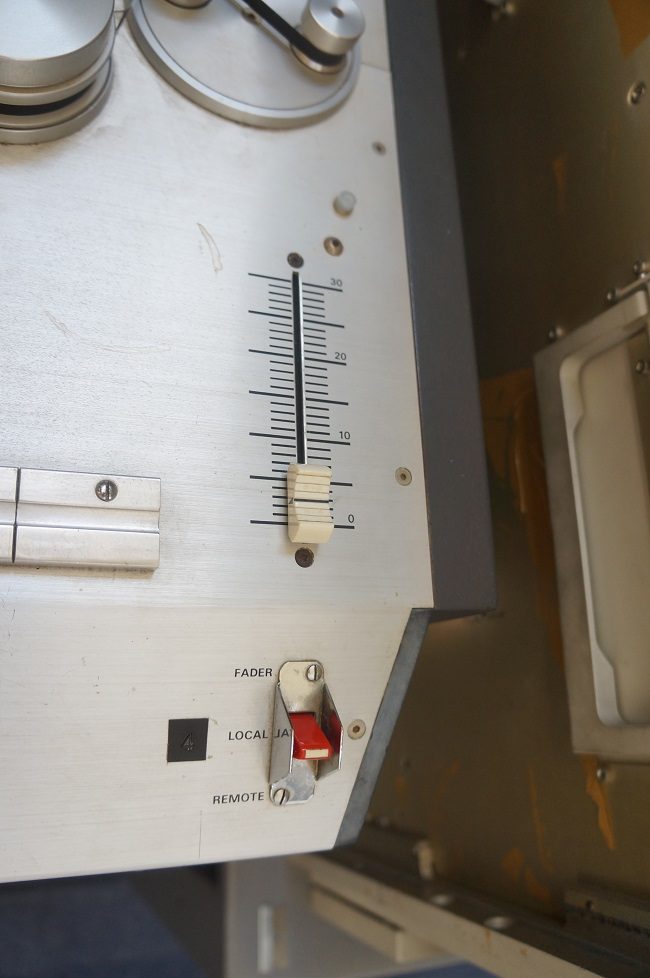

The telltale signs can be found in customised features, such as control faders and switches. These enabled sound levels to be controlled remotely or manually.

The presence of peak programme meters (P.P.M.), buttons that made it easy to see recording speeds (7.5/ 15 inches per second), as well as switches between cues and channels, were also specific to broadcast use.

Studer tape machines were favoured in professional contexts because of their ‘sturdy tape transport mechanism with integrated logic control, electronically controlled tape tension even during fast wind and braking phases, electronic sensing of tape motion and direction, electronic tape timing, electronic speed control, plug-in amplifier modules with separately plug-gable equalization and level pre-sets plus electronic equalization changeover.’

Because of Studer’s emphasis on engineering quality, machines could be adapted according to the specific needs of a recording or broadcast project.

For our ¼ inch reel-to-reel digitisation work at Greatbear, we have also adapted a Studer machine to clean damaged or shedding tapes prior to transfer. The flexibility of the machine enables us to remove fixed guides so vulnerable tape can move safely through the transport. This preservation-based adaption is testimony to the considered design of Studer open reel tape machines, even though it diverges from its intended use.

If you want to learn a bit more about the Equipment department at the BBC who would have been responsible for adapting machines, follow this link.

ADAPT, who are researching the history of television production also have an excellent links section of their website, including one to the BBC’s Research and Develop (R&D) archive which houses many key digitised publications relating to the adoption and use of magnetic tape in the broadcast industry.