The Teac A3440 is a classic reel to reel tape recorder from the late 1970s, early ’80s significant in that you could use it to make 4 track multitrack recordings at 15 inches per second, the professional tape recording speed. At the time there was precious little else around at the price to do this so this machine was perfect for small bands and studios who didn’t have the wallet busting amounts needed to buy a larger format 16 or 24 track recorder.

While the A3440 isn’t the last word in high quality analogue recording it has had some significant users in the past none less than Lee Perry who’d used the earlier but similar A3340 on his Heart of the Congos album.

the problems

This machine didn’t initially look heavily used, the heads had little wear but it hadn’t been used in a long while and there was a heavy build up of tape residue on the whole tape path. The capstan was very dirty and in these cases xylene is a more effective cleaner than IPA but don’t get it anywhere near plastic!

This A3340 powered up but the right hand tension arm was hanging at an odd angle and it wouldn’t play or wind.

Time to take it apart – the fake wood sides and rear panels get removed and it’s pretty easy to see what one of the problems is.

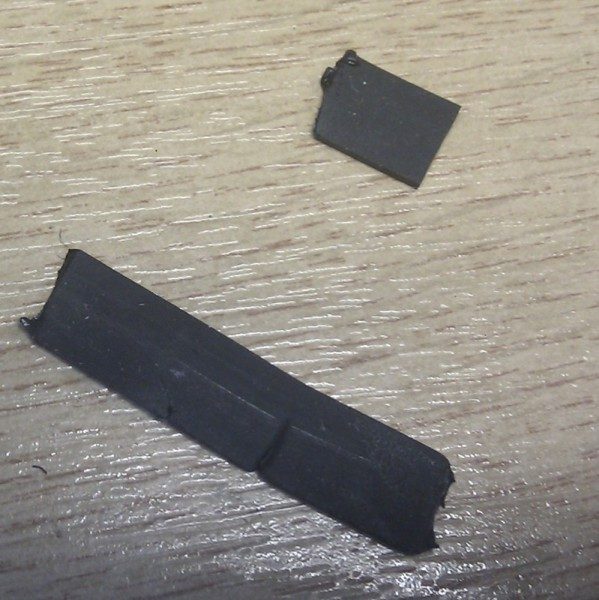

A very nasty ‘melted’ rubber capstan belt that took a fair while to scrape and clean off with IPA.

A new belt has purchased online – Teac parts in the UK are a big pain to get hold of through the official channels and I’ve given up contacting them unless I’m desperate for a part I can’t find anywhere else.

The other lack of drive was caused by broken micro switches. When the right hand tension arm is moved up, two micro switches behind the front panel switch power on for the capstan and reel motors. As this arm can get a los of use / abuse it’s common for the micro switches to crack. Both on this example were broken as was the small plastic piece that stops the arm moving too far down.

the repairs

To replace the capstan belt:-

- Remove both screws holding the capstan flywheel against the front panel.

- Make sure the flywheel is cleaned of all old belt debris.

- Make sure the motor wheel is cleaned of all old belt debris.

- Refit new belt over small motor wheel, then flywheel.

- Replace bracket remove in part 1, making sure you’ve cleaned off the old grease and regreased where the end of the capstan shaft can run.

Although not essential I took the opportunity to remove the whole capstan shaft, clean, check for wear and reoil before putting back. If you do this you will need to reset the endfloat though.

microswitches

It’s not possible or worthwhile trying to repair the microswitches as the modern equivalent that fits perfectly is very cheap. Two were purchased from Farnell and replacement is just a case of:

- Unscrew and move away the control PCB to get more space

- Make a note of or photograph wiring connections for switches.

- Unscrew and carefully desolder the existing microswitches.

- Connect wires and solder the new switches in.

The arm end stop was repaired easily with strong super glue and after many hours is still holding.

is it working?

In a word, kind of! The belt and microswitches got the deck and transport moving. It will pull tape and make a noise which is great but an annoying intermittent problem started to appear after some initial testing.

When play or wind are selected, large solenoids clunk and release the reel brakes and move the pinch wheel. This was working BUT occassionally and only in play the right reel brake solenoid didn’t move, leaving the brake on, causing the tape speed to slow, back tension to increase and wow to go crazy!

See our next post for the repair of this problem…