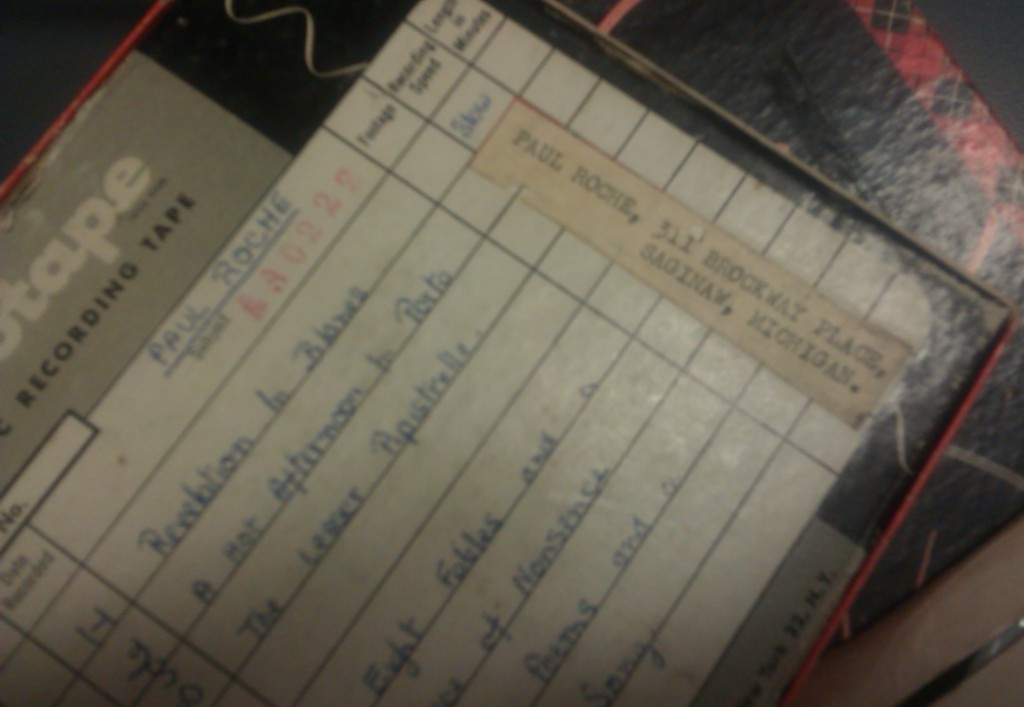

We were recently sent a very interesting collection of recordings of the late poet, novelist and acclaimed translator Paul Roche. During his colourful and creative life Roche published two novels, O Pale Gallellean and Vessel of Dishonour, and several poetry collections, and brushed shoulders with some of the 20th century’s most captivating avant-garde artistic and literary figures. His faculty colleague when he worked at Smith College, MA in the late 1950s was none other than Sylvia Plath, who pithily described Roche’s ‘professional dewy blue-eyed look and his commercially gilded and curled blond hair on his erect, dainty bored aristocratic head’.

His intense 30 year friendship with painter Duncan Grant was immortalised in the book With Duncan Grant in Southern Turkey, which documented a holiday the friends took together shortly before Grant’s death. The relationship with Grant has often eclipsed Roche’s own achievements, and he is often mistakenly identified as a member of the Bloomsbury group. Roche also achieved success beyond the literary and scholarly world when his translation of Oedipus the King became the screenplay for the 1968 film starring Christopher Plummer and Orson Welles.

The recordings we were sent were made between 1960-1967 when Roche worked at universities in America. Roche experienced greater professional success in America, and his translations of Ancient Greek are still used in US schools and universities. His son Martin, who sent us the tapes, is planning to use the digitised recordings on a commemorative website that will introduce contemporary audiences to his father’s creative legacy.

The Great Bear Studio has been pleasantly awash today with the sound of Roche reading poetry and his dramatic renditions of Sophocles’ ‘Oedipus the King’, ‘Oedipus at Colonus’ and ‘Antigone’. The readings communicate his emphatic pleasure performing language via the spoken word, and an unique talent to immerse listeners in images, rhythm and phrases.

Listen to Paul Roche reading his translation of ‘Antigone’.

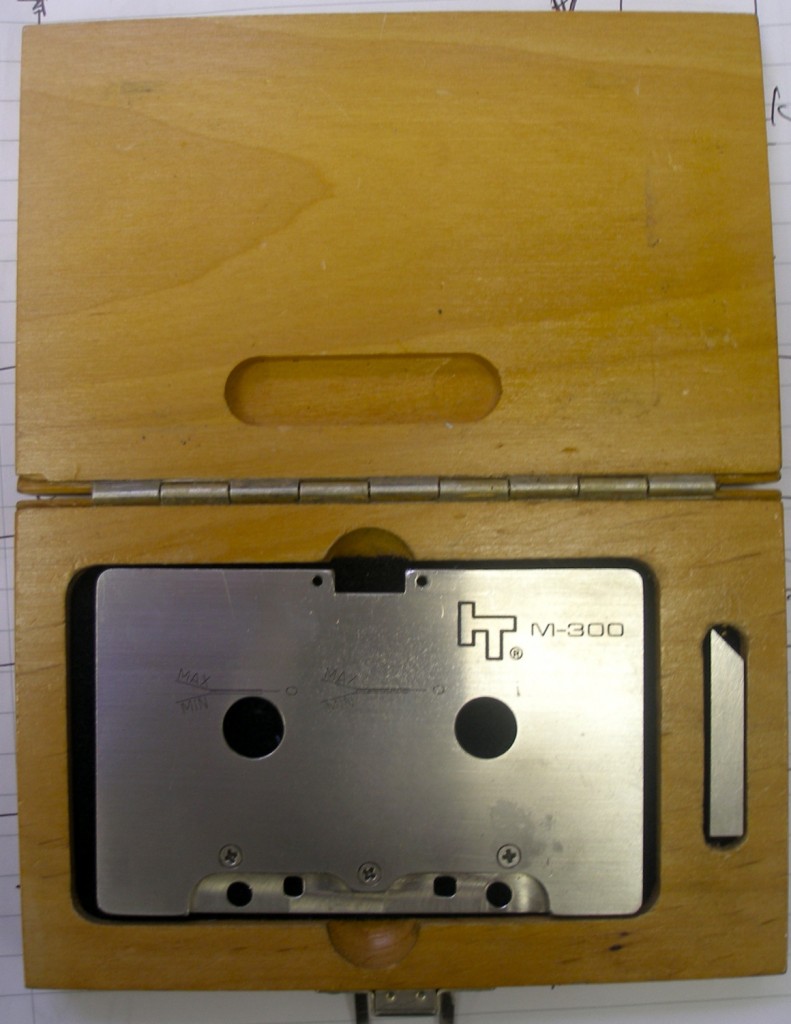

Our own pleasure listening to the recordings has however been disrupted because of frequent snaps in the tape. The tapes are covered in splices, which suggests they had been edited previously. Over time the adhesive glue has dried out, breaking the tape as it moves through the transport. The collection of tapes as a whole are fairly brittle because the base film, which forms the structural integrity of the tape, is made of acetate.

Canadian-based digitisation expert Richard Hess explains that

‘Acetate was the first widely used base film, with Scotch 111 being in production from 1948 through 1972/73, a total of 24-25 years. Acetate tape is generally robust and has the advantage of breaking cleanly rather than stretching substantially prior to breaking when overstressed. Acetate tapes residing in collections are over 30-years-old, with the oldest being over 60-years-old.’

The big downside to acetate is that when it degrades it loses its flexibility and becomes a bit like an extended tape measure. This means it is harder to pass the tape consistently through the tape transport. This is colloquially known in the digitisation world as ‘country-laning’, when the tape changes shape in all dimensions and becomes wiggly, like a country lane. To extend the metaphor, a well functioning tape should be flat, like, one supposes, a motorway.

If you are reading this and wondering if the base film in your tape is made of acetate, or is made of another substance such as paper or polyester, you can perform a simple test. If you hold the tape against the light and it appears translucent then the tape is acetate. There may also be a slightly odd, vinegar smell coming from the tape. If so, this is bad news for you because the tape is probably suffering from ‘Vinegar Syndrome’. Richard Hess explains that

‘Vinegar syndrome occurs as acetate decomposes and forms acetic acid. This is a well-known degradation mode for acetate film. High temperature and humidity levels, the presence of iron oxide, and the lack of ventilation all accelerate the process. Once it has started it can only be slowed down, not reversed.’

Acetate tape is also particularly vulnerable to excessive heat exposure, which makes it shrink in size. This is why you should never bake acetate tape! When acetate tape is exposed to heat it reaches what is known as the liquid-glass transition phase, the temperature where the material composition starts to change shape from a hard and relatively brittle state into a molten or rubber-like state. Although glass transition is reversible, it certainly is destructive. In other words, you can change the tape back from molten to a hard substance again but the tape would be unplayable.

While acetate backed tape has certain advantages over polyester tape in the migration process, namely it is easier to cleanly splice together tape that has broken as it has moved through the transport, unfortunately acetate tape is more fragile, and can get extremely stiff which makes it difficult to play back the tape at all. Even if you can pass the tape through the machine it may snap regularly, and will therefore require a lot of treatment in the transfer process. So if you have a valuable tape collection stored predominantly on acetate tape, we strongly recommend getting it migrated to digital format as soon as possible due to the fragility of the format. And if that whiff of vinegar is present, you need to move even more quickly!